PREVYMAN and Vision Zero: a new way of doing prevention.

Where have I been and what happened to me?

For a long time I have seen that there are many prevention technicians disheartened with the results of their work because they see that their efforts do not obtain the expected results. In particular, I had a long conversation with a colleague from many years ago. He works as Prevention Manager in a company, with an approximate volume of 550 workers. You believe you have reached a stalemate, you consider that you comply with the regulations on occupational risk prevention, and this is contemplated in the Audits carried out, you have technological means of support and apparently adequate management of the risk.

But workplace accidents do not decrease, their accident rates are above the sector average and there is no real integration of prevention in all departments. It is an example of what worries me at this moment and I decide to help you.

What means does the company have to avoid this situation?

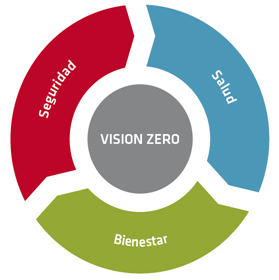

I go to the Company accompanied by a Prevention Technician from its Mutual Collaborator with Social Security with the firm objective of making our colleague and the General Management of the Company see that prevention must be considered in a less documentary way, taking more into account people and their differential characteristics. If we want results we must find a common interest between the company and workers, such as health, and align prevention with the company's objectives. To achieve this we must all work together on the following factors of the Organization: commitment, leadership, honest communication, preventive culture and learning from mistakes. In short, we want to talk to you about Zero Vision a new way of approaching prevention management in the company focused on people being the solution and with the vision that all health damage is preventable through the training of people and their involvement in the process.

Vision Zero___ is developed around 7 Golden Rules that you can consult in our prevention portal Previene: Leadership, Identify Hazards, Define Goals, Ensure a Safe and Healthy System, Use safe and healthy technologies, Improve Qualification as well as Invest in People.

The General Directorate, given the situation of stagnation in prevention, has seen with favor what we are proposing about Zero Vision. We hold more meetings in order to define a Work Plan focused on improving two-way communication, involving all people, generating a preventive culture, bringing it closer to Zero Vision.This Plan has the following master lines, related to Zero Vision, in relation to the transversality of occupational risk prevention and with the system already implemented by the Company:

- Transmit from Management the desire for change to all workers in person and create a work group. The group must be led by the top person in charge and will include middle management and other workers who support the change. Golden Rule No. 1: Leadership and commitment.

- Identify the starting point by self-diagnosis using the quizzes Vision Zero.

- Review Preventive Activity Planning involving all workers, establish small preventive effort objectives, not accident rate objectives and adjust periodically. Golden Rule No. 3: Define goals.

- Redesign the Prevention Plan, establishing the company's vision in relation to prevention and assigning specific functions to middle managers, training them in team management, communication, conflict resolution, etc... Golden Rule No. 4 and 6: Ensure a safe and healthy system and Train people.

- Know the risk assessment and investigations of harm to people, share important risks and preventive measures involving managers and workers. Golden Rule No. 2 and 5: Identify risks and Use safe and secure technologies healthy.

- Organize brief but frequent training actions, with the help of more experienced colleagues, including gamification tools or virtual training.Golden Rule No. 7: Invest in the people___H TMLTAG279___.

- Facilitate continuous communication___ about the objectives achieved and celebrate achievements, recognize personal effort, talk to workers, clarify doubts, ask for opinions/suggestions, find out the reasons for errors, know people's daily lives and establish communication channels such as suggestion boxes, bulletin boards, etc... Golden Rule No. 1: Leadership and commitment.

What results have been obtained?

12 months have passed since the defined Plan began to be implemented. The latest report carried out by the SPP shows the following results:

- 50% more preventive improvement actions have been carried out and the accident rate due to work accidents has decreased by 46% in relation to 12 months previous.

- This has meant the reduction in administrative sanctions and judicial processes related to work accidents.

- The Production Department verifies an increase in productivity, according to the Company's parameters, of 6% comparing with the previous 12 months.

- The measurement of the work environment and the evaluation of psychosocial risk, according to the Human Resources Department, yields a significantly better result than that obtained the previous year. An increase in general commitment is observed with more suggestions for improvement every day.

- The results of the Company, maintaining the same level of billing and associated resources, have increased by 7.5%.

- The Company has been awarded for its management model in reducing accidents, which has made it an example of safe, healthy and sustainable.